How Leather is Made

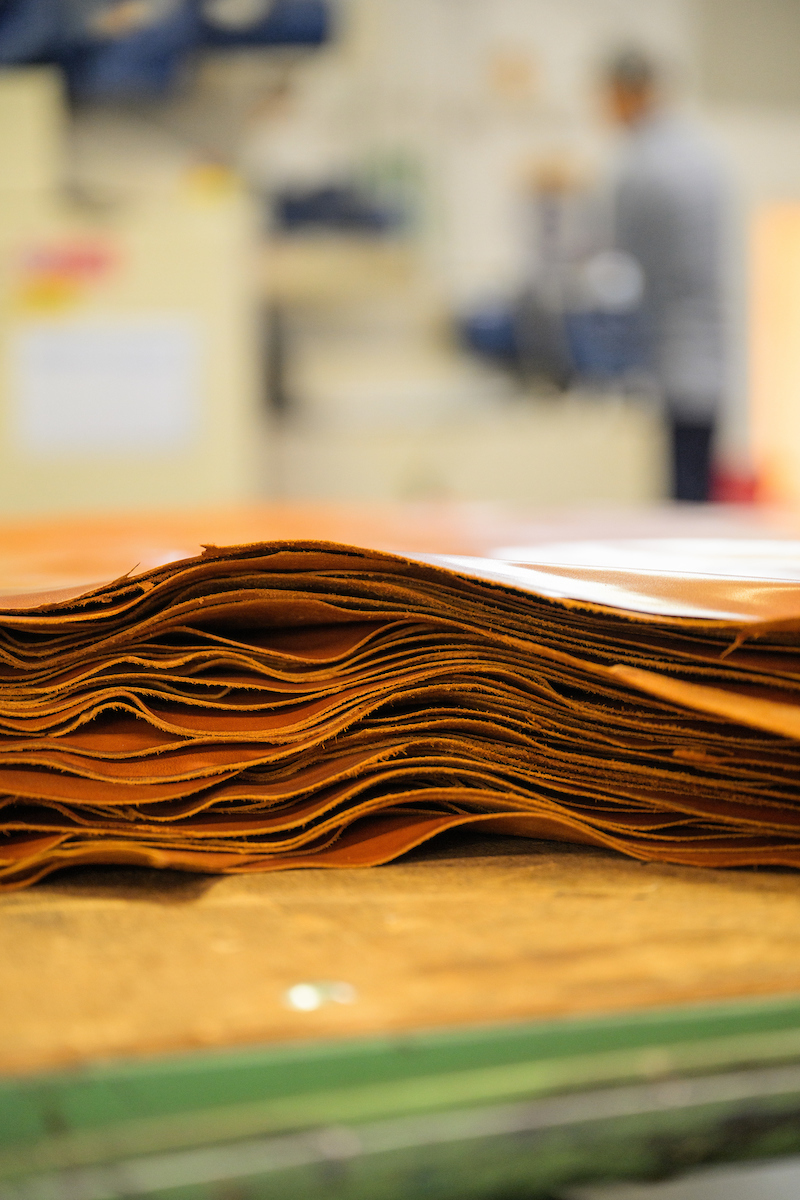

Tanning

Leather tanning is the process of turning cleaned, perishable raw hides or skins into leather to keep their natural beauty and characteristics. The most common methods of tanning are Chromium and Vegetable Tanning.

Chromium-Tanning uses chromium salts to produce softer and more supple leather that resists discoloration and water damage. This method is widely used for tanning.

Vegetable-tanned leather is created using tannin and other natural ingredients from trees and plants. It results in leather with greater body and firmness compared to chromium-tanned leather.

During the tanning process, hides are often treated with agents to improve their strength and desired characteristics. This step is known as Retanning.

Chromium-Tanning uses chromium salts to produce softer and more supple leather that resists discoloration and water damage. This method is widely used for tanning.

Vegetable-tanned leather is created using tannin and other natural ingredients from trees and plants. It results in leather with greater body and firmness compared to chromium-tanned leather.

During the tanning process, hides are often treated with agents to improve their strength and desired characteristics. This step is known as Retanning.

Dyeing

Drum dyeing is the process of immersing the leather in the dye and tumbling it in a rotating drum to ensure maximum penetration of the dye throughout the hide. Aniline dye is a translucent water-based dye without any added pigments. As aniline dye is absorbed, natural markings and inherent characteristics such as scars and wrinkles are brought out in each hide. Since absorption of dye may differ from area to area, slight variations in color are usually exhibited throughout the hide, much like wood varies when stained. These distinctive markings and nuances in texture and color are a testament to its authenticity.

Finishing

After dyeing, leather goes through processes like embossing, milling, or waxing to get the desired look and feel. Some leathers are naturally milled to enhance the grain or make them feel softer. Many of our leathers are treated with a mix of waxes and oils that soak into the hide and make it naturally resistant to moisture.

Similar to the grain of fine wood, leather has unique natural features like healed scars, wrinkles, and differences in grain. Most of our leather is not artificially finished, so any natural texture variations are not hidden. With time, the leather will develop a rich and beautiful patina that gives it its own charm and character.

We use different techniques during the finishing process to improve the natural appearance of our leathers. For example, using heat and pressure creates a clear, glossy surface and enhances moisture resistance. If you want consistent color and maximum protection against wear and scratches, we have leathers with a protective pigment or topcoat coating.

Discover our Leather

With thousands of leathers to select from, you can customize your project to fit any style or preference.

!